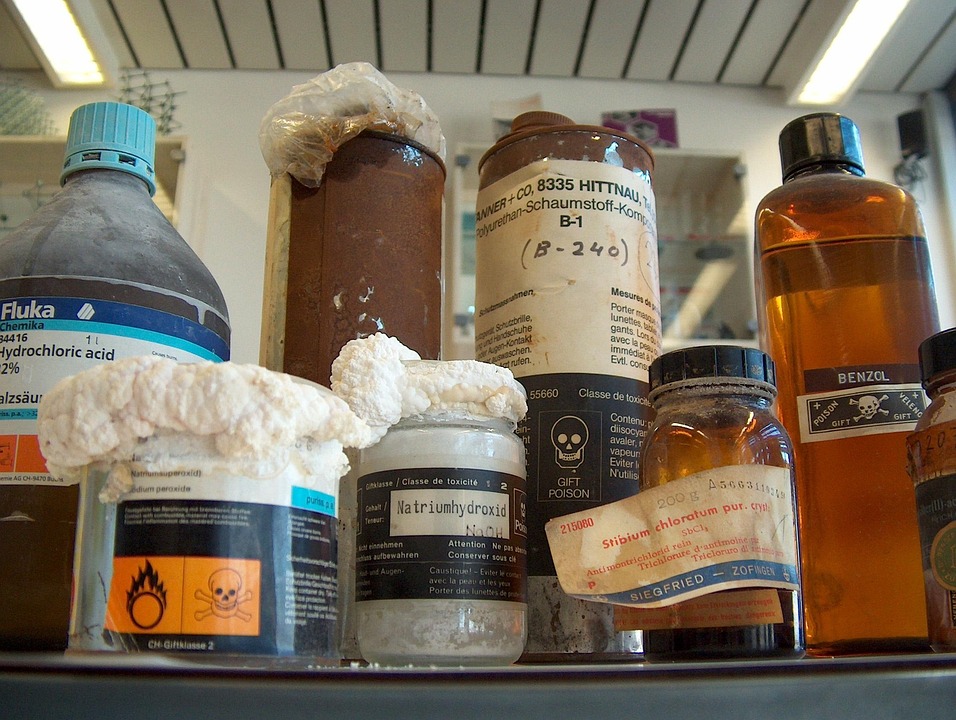

Whatever dimension a chemical spill might be, it should be considered an emergency and, for that reason, be resolved instantly. Industrial facilities and facilities often take care of harmful liquids. However, firms with fewer threats can likewise gain from having a spill set in position.

Specific poisonous chemicals can create serious diseases or even death. Some substances can cause fire or long-term ecological damage. Spill kits can assist you in minimizing and even preventing these results. It is an all-in-one container storing tools and equipment for tidying up dangerous spills.

Spill Kits Information

What Does a Spill Package Include?

Spills can be small and also huge. Tiny spills are those where the compound can be managed right away with neutralization or absorption. A small spill may be subordinate and will not usually require emergency action teams.

On the other hand, big spills posture fire, surge, residential property damage, direct chemical exposure, health, and additional safety and security dangers. These require emergency team action within and outside the prompt release location.

When is a Spill Kit Called For?

Spills can occur anytime and anywhere water or oil-based chemicals are utilized, saved, or moved. Organizations and centers that handle hazardous chemicals should have spill kits in emergencies. Some examples of those requiring these sets are mining businesses, light and heavy industry firms, vehicle repair centers, workshops, hospitals, dining establishments, and more.

For example, if the equipment has leaked water or various other liquid, this could be a sliding or falling threat. A spill kit can be utilized to clean this up. In some cases, when such troubles still linger, absorptive products have to be left in place.

Suppose your facility has the prospective to pollute a close-by body of water. In that case, you should consist of your Spill Prevention Control and Countermeasures (SPCC) strategy that you have spill sets to handle toxic spills.

You can add these into your spill monitoring practice to stop the discharge of unpermitted harmful pollutants into nearby rivers. This requires larger kits because of feasible, more considerable spill quantities.

Spill Containment

Of course, having spill packages will certainly not suffice. A detailed spill reaction strategy should additionally be in the area. It must include kit use, containment procedures, backup plans, and more.

To guarantee that you pick the ideal container for spill emergencies, consider the flexibility, size, and disposal requirements. If you need something to hold significant amounts of liquid, choose a set with a strap or wheels for more straightforward handling.

Secondary containment can be performed in giving and storage space places. For example, spill control can be released through drainpipe covers and diverter dikes loaded with water. Some control choices are outdoor storage space sheds, spill pallets, and management.

Spill kits do not work on their very own. There needs to be a mix of cleaning, control, and PPE. Being also prepared for tiny spills can stop accidents as well as an interruption to day-to-day business tasks. A subordinate spill can become an even bigger emergency if not attended to instantly.